Provides insight into packaging materials, how much is in stock, at the customer and how much can be returned to the supplier. Checks to prevent more being returned than delivered, this prevents additional logistics and handling costs. Also prevents customers from making money on your packaging materials due to different deposit amount. This feature makes it possible to add packaging materials to the orders from the warehouse process. And also provides a Packaging workspace to manage all the packaging materials.

• Packaging materials must be registered as a regular item (Product type is “Item”), marked as “Packaging”.

• Packaging items are kept on a Fixed location and are not License plate controlled.

• Packaging item can be added to order manually or via the Warehouse management app.

• Packaging transactions records are created, and Packaging balance is adjusted at the posting of Packing slip/Product receipt.

• Packaging item setup is not forced by the system, it must be done manually and well-considered.

• In case of cash or prepayment (Counter sales), the packaging item should be add manually before payment or second payment should be made after packaging is added.

• Packaging item added from the Warehouse management app, will not be included in Order cost calculation, nor it will be take into account to determine if the Order cost threshold has been passed.

• Credit management checkpoint on 'Order complete' will not take the Packaging item added via the Warehouse management app into account. So the total order value may exceed the credit limit amount. Credit management checkpoint on 'Packing slip' will take the added Packaging item into account, but is it desired to block an order while it is already at the bay door? Please consider the setup well.

• Do not use 'Packaging' item in the Action discount Product category with an auto-add supplementary item. Because this supplementary item will be automatically added, when the Packaging item is added from the Warehouse management app.

• Adding Packaging item to the existing purchase order via Warehouse management app is not possible if Active change management (workflow) is enabled. The following error message will be shown: “Changes to the document are only allowed in state Draft, because change management is activated.”

Warehouse management > Setup > Packaging parameters > tab Packaging

| Field | Description |

| Enable Packaging | Enable packaging functionality |

Warehouse management > Setup > Packaging parameters > tab Number sequences

| Field | Description |

|

Number sequence code |

The unique identification of the packaging transaction |

Warehouse management > Setup > Packaging > Packaging reason codes

The packaging balance of a customer or vendor can be adjusted via packaging transaction form. This option is necessary, due to lost or broken packaging material. When performing those corrections, reason code is a mandatory field. Reason codes can be pre-defined in this table.

| Field | Description |

| Packaging reason code | Reason code for packaging balance correction |

| Description | Reason code description |

Product information management > Products > Products > Product details

Parameter Packaging is introduced on the Product detail form. The concept is, that in case of multiple company structure, packaging item is packaging item in all the companies. This parameter is also available on forms New product and New released product (EcoResProductCreate).

| Field | Description |

| Packaging | This item is a packaging item |

Parameter Packaging is also displayed (display method) on the Released product details form. Not editable!

The parameter Packaging is also added to the following order line details (tab General), to indicate the packaging item. Again, only display, not editable:

• Sales orders

• RMA order

• Purchase order

Packaging item conditions:

• Marked as “Packaging”

• Product type is “Item”

• WHS enabled

• Has a Fixed location

• Is not license plate controlled

This should be covered with setup, it is not forced by software.

In the Packaging workspace there is a tile “Create packaging item”, which will open the “New released product” form where the parameter “Packaging” will be Yes by default and greyed out, so it cannot be edit.

The Packaging workspace also contains a tile “Packaging items”, to navigate to the Released product details form with filter on parameter Packaging, containing only the packaging items. The Packaging workspace also contains a tile “Packaging items without fixed location”, since Fixed location is one of the conditions for the Packaging item setup, this can be monitored with this tile. The number on this tile should be 0.

Warehouse management > Setup > Mobile device > Mobile device menu items

To be able to add Packaging items to existing orders from the warehouse management process, a mobile device menu item for packaging must be created. Packaging does not provide this mobile device menu item out of the box. It must be created manually. We recommend to name it “Packaging”. What is provide within the Packaging product is the Activity code “Packaging registration” that must be used for this mobile device menu item. The Mode is “Indirect”. The “Packaging” mobile device menu item can be added to the mobile device menu Inbound as well as Outbound, as a separate mobile device menu item or as an additional detour step within the steps of e.g. Sales picking.

Before detour setup can be made, it is necessary to load the default setup. To perform this action follow the path below and press on the button ‘Create default setup’:

Warehouse management > Setup > Mobile device > Warehouse app fields names

Once this is done the detour can be setup following the path and the steps described below:

Warehouse management > Setup > Mobile device > Mobile device steps

Select the step from which you would like to start the detour Packaging, press the Add step configuration, select the concerning Menu Item, e.g. Sales picking, determine which information will be send to detour and which will get back from detour, by pressing the Add button on the tab “Available detours (menu item)”. See an example below:

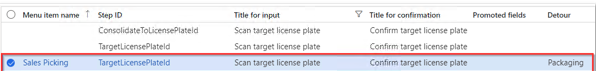

In the Menu item “Sales Picking” at the step “Confirm target license plate”, a detour step Packaging has been added:

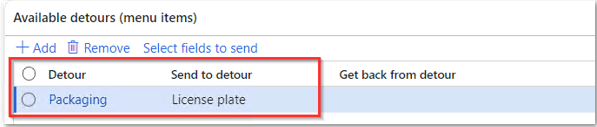

At available detours, Packaging has been selected

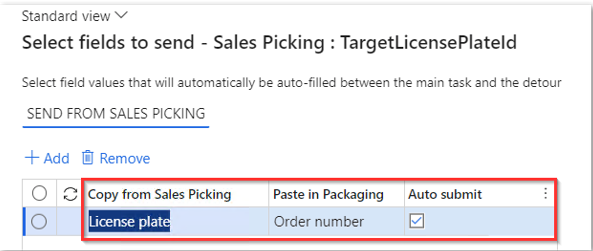

In the ‘Select fields to send’ section, License plate is selected to be copied to the Packaging Order number, this is used to connect with the correct order.

Packaging item can only be added to the existing orders with order status “Open order”. Orders with status “Delivered” or “Invoiced” will cause an error.

This mobile device menu item can only process item that are marked as Packaging (parameter Packaging = Yes)

If the Packaging functionality is going to be used intercompany, parameter “Allow indirect creation” should be set to Yes on the concerning customer in de selling company.

| Field | Description |

| Transaction type | There are four transactions types: Purchase: transactions coming from the purchasing process, including return purchase order. Sales: transactions coming from the sales process, including RMA. Correction for vendor: corrections made on a vendor account. Correction for customer: corrections made on a customer account. |

| Account number | Vendor or customer number (depending on Transaction type) |

| Name | Name of the vendor/customer |

| Reference number | Related order number |

| Reference lot | Inventory Lot ID of the related inventory transaction |

| Item number | Item number (packaging item number) |

| Product name | Name of the packaging item |

| Unit | Unit of measurement (Sales/Purchase depending on type) |

| Quantity | Transaction quantity |

| Date | Transaction date |

| Packaging reason code | Packaging reason code for the correction transaction |

| Field | Description |

| Customer | Customer account |

| Item number | Item number (Packaging item number) |

| Quantity | Transaction quantity |

| Unit | Unit of measurement |

| Line status | Concerning order line status |

| Type | Type of order Sales order or Returned order |

| Delivery type | Delivery from Stock or Direct delivery |

| Ship date | Date of shipment |

| Lot ID | Inventory transaction lot ID |

| Field | Description |

| Vendor account | Vendor account |

| Purchase order | The related purchase order |

| Item number | Item number (Packaging item number) |

| Quantity | Transaction quantity |

| Unit | Unit of measurement |

| Line status | Concerning order line status |

| Type | Type of order Purchase order or Returned order |

| Delivery type | Delivery from Stock or Direct delivery |

| Confirmed receipt date | Confirmed receipt date |

| Lot ID | Inventory transaction lot ID |

Tab Sales and Purchase is showing the open transactions. Open transactions are transactions of the packaging item on Return sales order, Return purchase order and/or Direct delivery order, were the Packing slip/Product receipt is not posted yet.

Every transaction of the packaging items (items that are marked as packaging), are recorded in the Packaging transaction table. There are two different type of transactions here. The one created by the system (Sales/Purchase), because a packaging item is used in a sales or a purchase process. These records are created in the Packaging transaction table at the moment that the Packing slip or Product receipt is posted. The one created manually by the user (Correction vendor/customer), to make a correction in the customer or vendor balance. Packaging transactions corrections are also meant to be used for creating a beginning balance for customers and vendors. We recommend to create a specific Packaging reason code for that, "Begin balance" or likewise. Another reason for corrections is the purchasing of packaging items. Purchased packaging item are not going to be send back to the vendor, so keeping a balance for that vendor makes no sense. With Packaging transaction correction it can be leveled out to 0. Also here, we recommend a specific Packaging reason code.

Use the button New, to make a correction transaction. A Packaging reason code is mandatory. It is not possible to delete records from the packaging transaction table. New packaging transaction correction can also be made via Packaging workspace “Create correction” tile.

Packaging transactions list page can also be found on the modules Accounts payable and Accounts receivable. By default filtered on the concerning Transaction type.

Account payable > Inquiries and reports > Packaging > Packaging transactions vendor

Account receivable > Inquiries and reports > Packaging > Packaging transactions vendor

Warehouse management > Inquiries and reports > Packaging > Packaging balance

| Field | Description |

| Type | Shows the type of the balance, vendor or customer. Used to filter in the concerning modules. |

| Account number | Vendor or customer account number |

| Field2 | Enter description here |

| Name | Name of the vendor/customer |

| Item number | Item number (packaging item number) |

| Unit | Unit of measurement (Inventory unit) |

| Quantity | Balance quantity per given date |

| Open quantity | Quantity on open orders (in expectation), Return order and Direct delivery order |

| Total quantity | Balance quantity including the order orders |

| Date | Balance date |

In the packaging balance table the balance per customer/vendor and packaging item is kept by. Every packaging transaction results in a new balance. Only the most recent balance is shown. To see the whole balance history, parameter Show can be switched to All.

Packaging balance can also be found on the following menu items and forms. By default containing the filter on vendors/customers and/or concerning vendor or customer.

Account payable > Inquiries and reports > Packaging > Packaging balance vendor

Accounts payable > Vendors > All vendors > navigation pane Procurement > Related information

Account receivable > Inquiries and reports > Packaging > Packaging balance vendor

Accounts receivable > Customers > All customers > navigation pane Sell > Related information

Sales order:

Account receivable > Orders > All sales orders > navigation pane General > Customer

Purchase order:

Account payable > Purchase orders > All purchase orders > navigation pane General > Vendor

Customer service:

Counter sales > Orders > Customer service > navigation pane Customer > Details

Return order (RMA):

Account receivable > Orders > All return orders navigation pane General > Related information

Packaging balance is available on the list page and on the individual orders.

When creating return order lines, sales (RMA or negative sales order lines) or purchase (return purchase order lines), the balance of the concerning vendor/customer is checked. The balance should be sufficient to cover the entered quantity. It is not allowed to send or receive more packaging items than, what the customer received from you or what you received from the vendor, including the packaging item in transit. The balance check is based on the following formula:

1. Packaging balance customer/vendor and item (+)

2. Quantity taken from direct delivery purchase/sales orders (from the customer/vendor and item), not received/delivered and having a date equal to today or in the past (-/-)

3. Quantity taken form other return orders (for customer/vendor and item) not yet received/delivered.

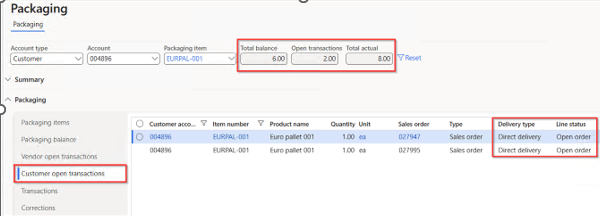

Here is an example based on customer 004896 and item EURPAL-001:

The current balance is 6. But as we can see, there are two direct delivery orders on the way to the customer 004896, containing item EURPAL-001, total quantity of Open transactions is 2. That means that customer 004896 is allowed to send 8 of the EURPAL-001 back.

If a RMA order is created for this customer item combination with quantity 9, the system will show an error message.